Perfect Drop

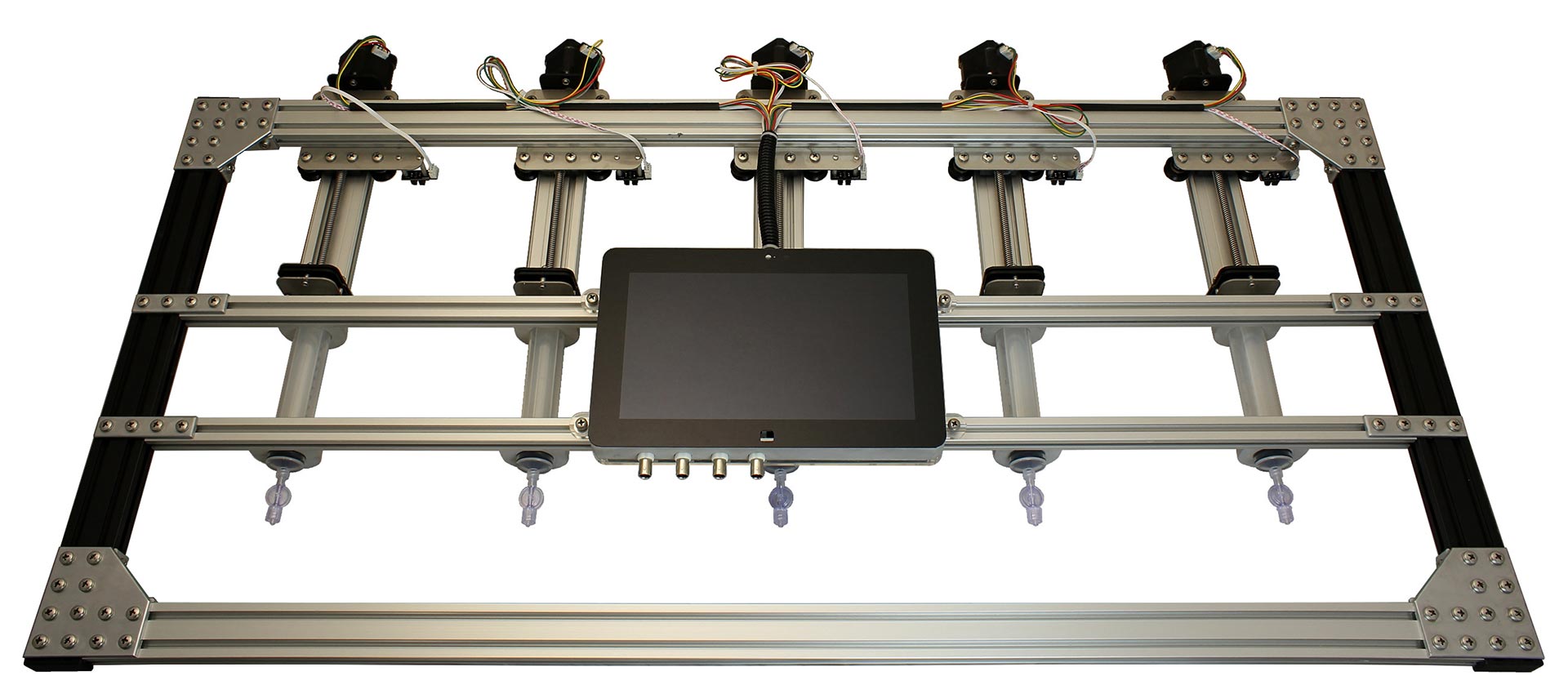

Scales as you do. Liquid-Ion's patent-pending delivery system features rugged, corrosion resistant construction to meet the challenges posed by even the largest hydroponic reservoirs. Injector motors ensure crops always have the nutrients they need to be productive. Individual ion control puts the grower in the driver's seat.

|

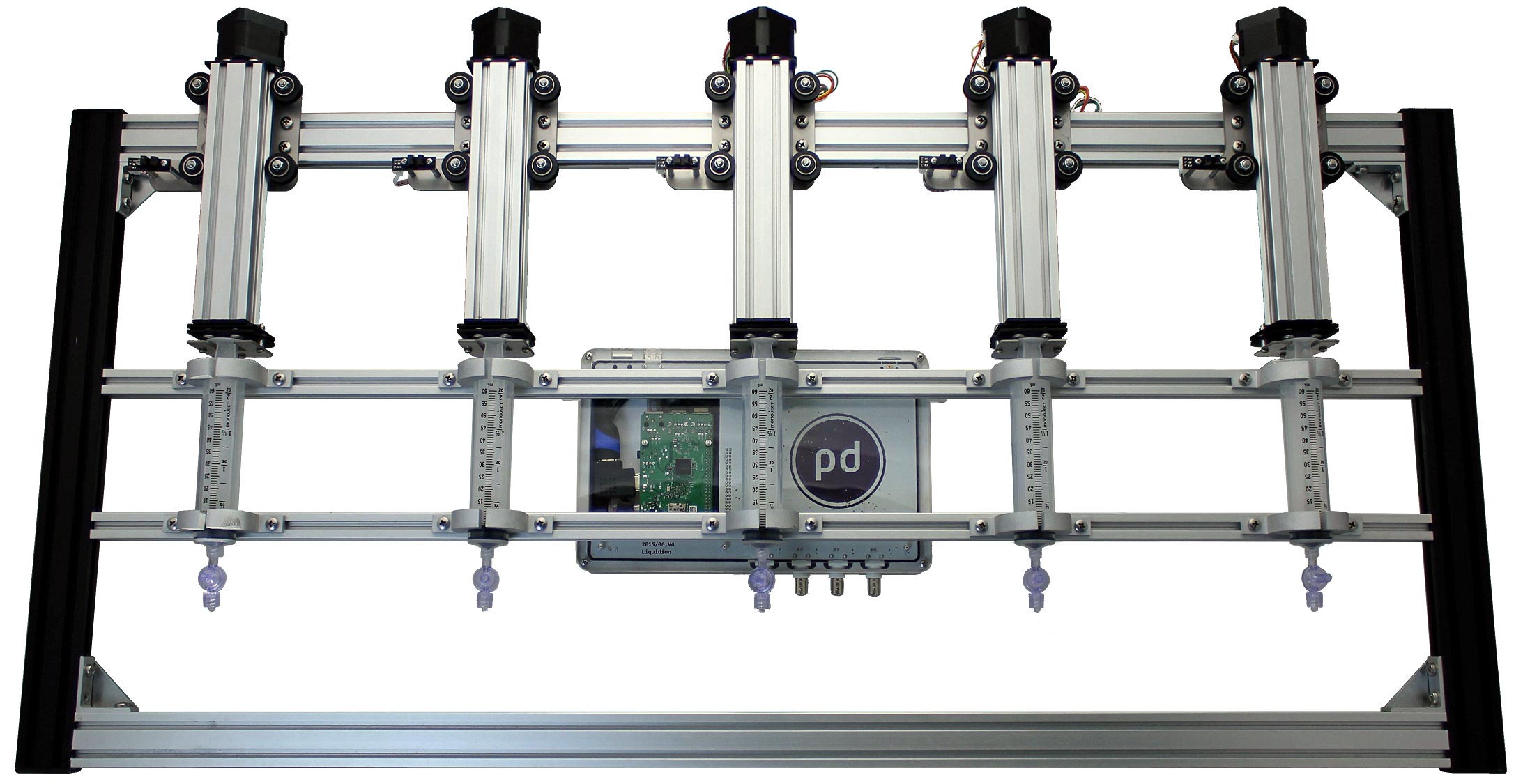

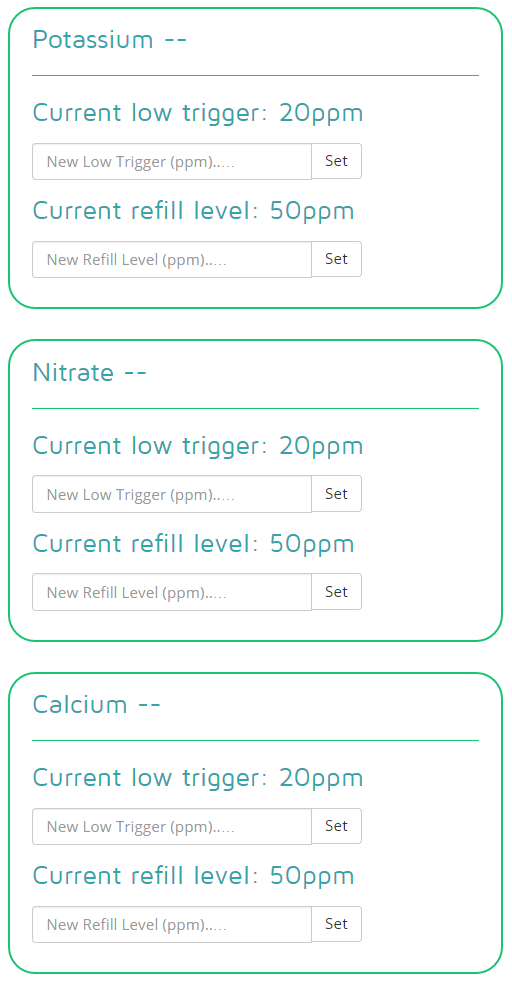

How it WorksFour waterproof ion-specific electrodes (ISEs), specific to the critical macronutrient ions: nitrate (NO3-), potassium (K+), calcium (Ca2+), as well as pH, are submerged into the main reservoir of a recirculating system. Each ISE sensor independently transmits to Perfect Drop's onboard control system via custom noise removing circuitry. Once cleaned of noise, the ISE signals are converted into a physically meaningful measurement in parts per million (ppm), and compared to grower defined thresholds. This comparison is made in near real-time, to enable immediate detection of key macronutrient deficiencies. Once an ISE measures a deficiency, a unique refill solution (not pictured) to that ISE is dosed back into the reservoir, with the pH ISE having two refill solutions. Each of the five refill solutions is connected to its own syringe/injector motor, and to the central reservoir via check valves. The volume of refill solution needed to rectify the ion-deficiency is calculated dynamically, and, once determined, an injector motor fills up the syringe, before ejecting the solution into the reservoir. Multiple ion deficiencies are handled by driving one injector motor at a time. |

Effortless Control

A 10" HD touchscreen allows for easy on-site control. When offsite, Perfect Drop's onboard Wi-Fi helps you stay connected to your hydroponic system. Explore Perfect Drop's full cloud capabilities, and see how it can provide novel insights into your crop and strain.